Implementing Lean Principles for Waste Reduction in Manufacturing Production Lines

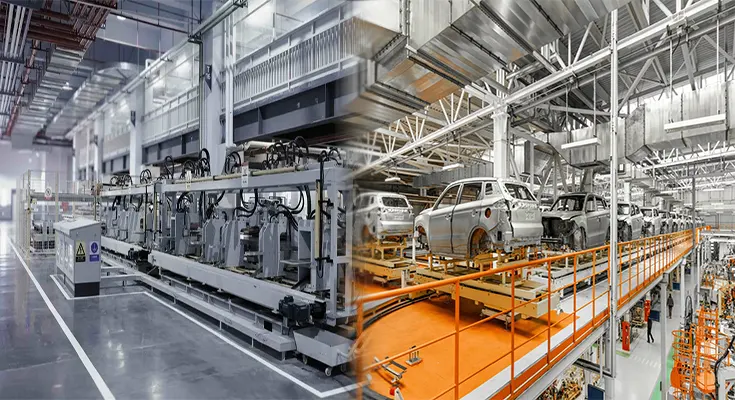

In today’s competitive global marketplace, manufacturers are constantly striving to increase efficiency, reduce costs, and improve productivity. One proven methodology that has gained traction in the manufacturing industry is Lean manufacturing, which focuses on identifying and eliminating waste to streamline production processes and enhance overall performance. By implementing Lean principles, manufacturers can optimize their production lines and achieve significant improvements in efficiency and profitability.

One of the key objectives of implementing Lean principles in manufacturing production lines is to identify and eliminate various forms of waste that hinder operational efficiency. Waste, as defined by Lean methodology, includes anything that does not add value to the final product or the customer. This can include unnecessary movement, overproduction, inventory excess, waiting times, defects, and underutilized talent and resources. By identifying and addressing these sources of waste, manufacturers can streamline their processes, improve product quality, and reduce operational costs.

One Lean principle commonly …

Implementing Lean Principles for Waste Reduction in Manufacturing Production Lines Read More